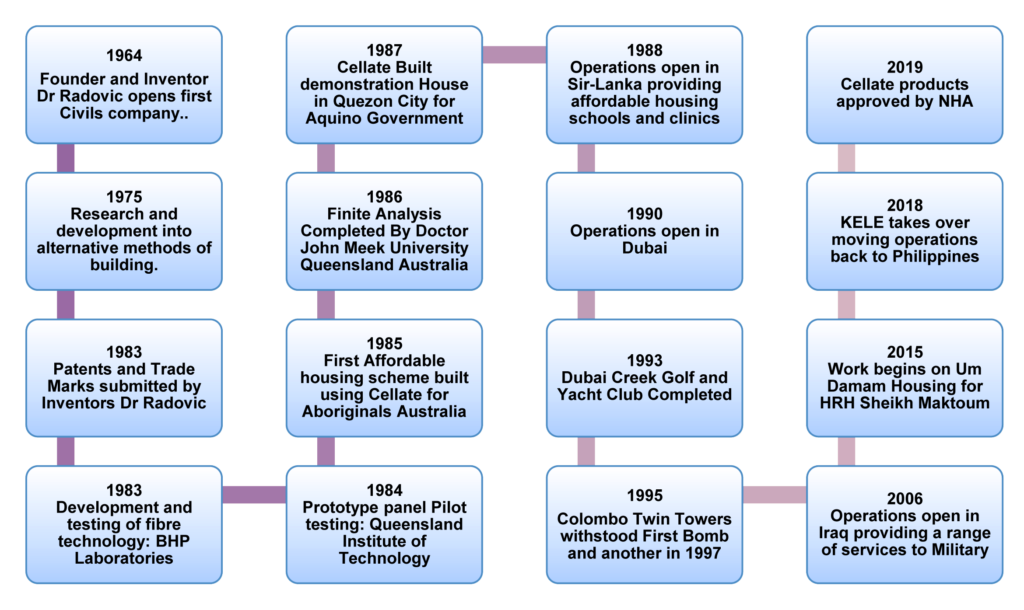

CELLATE COMPANY OVERVIEW AND HISTORY

KELE use Cellate technology exclusively, which was first conceived in 1964 by the founder and world patented in 1985 by a core team of professionals. We specialise in providing a full turnkey service delivering both affordable and prestigious developments within key sectors. KELE manufacture a range of Ultra High Strength precast structural elements that are the most advanced on the market and provide into numerous business sectors within are business streams which are Buildings, Infrastructure and Defense. Please Note that defence information in this document is limited for security purposes, please ask for more details. KELE are an international company and establishing a new headquarters in the Philippines owned for both coordination of development programmes and our manufacturing of fibre steel which is a key component of our patented Cellate technology. LEFT: World Trade Centre Colombo Sri Lanka constructed using Cellate Panels and was blown up twice in separate terrorist attacks !!.

SERVICE AND CAPABILITY OF CELLATE

- Economical – Proven Affordable Solutions.

- Full Turnkey Service.

- Engineering Excellence

- Architecture, Urban Development and Master Planning

- Product Superiority In All Regards Compared With Alternative Materials.

- Environmentally Sustainable – LEED Green Footprint Approved.

- Low Risk Fast Production and Installation.

- Superior Performance – Very Long Life and Low Maintenance

- Earthquake, Fire, Flood, Storm and Projectile Resistant

- Uses Local Materials and Labour.

- Cellate Core Components Manufactured by Kele.

- Services are installed during manufacturing and have ready to paint surfaces.

- Lower Insurability

- Designs validated by Lloyds of London

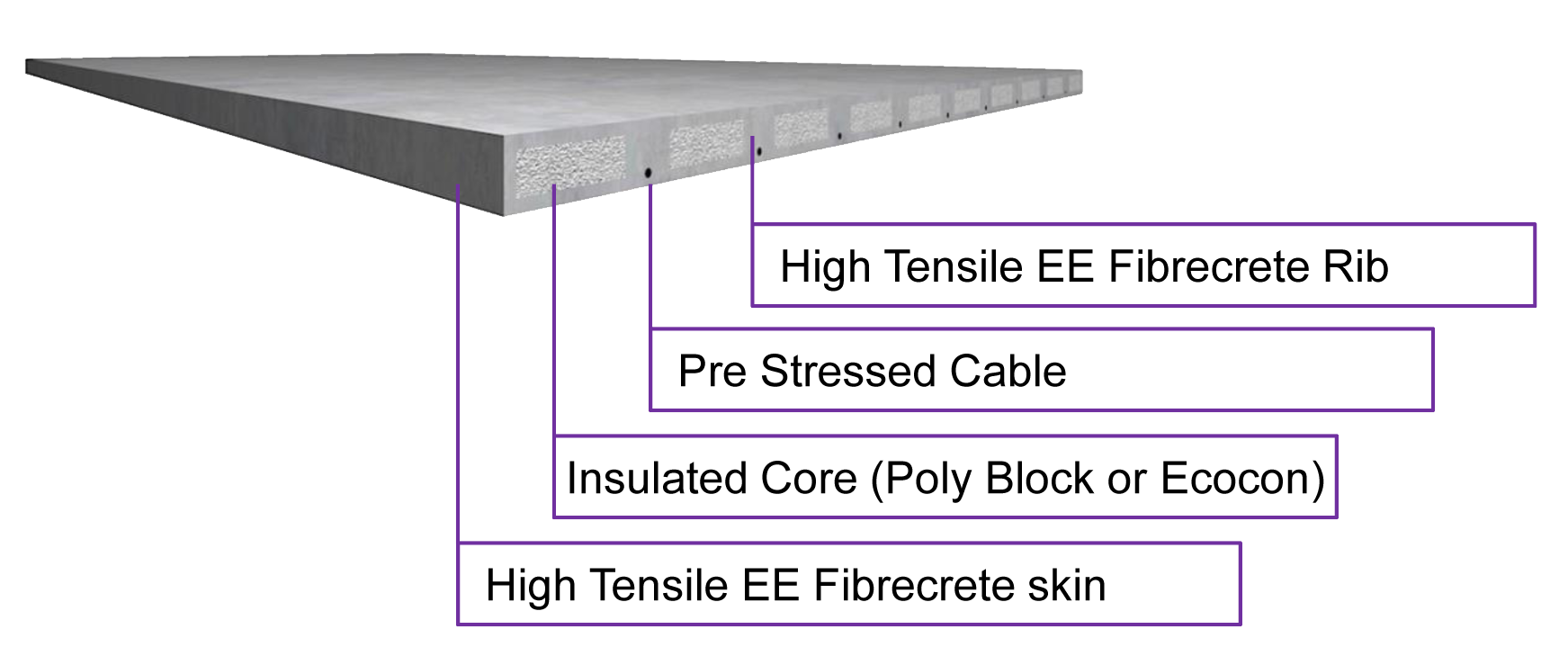

CELLATE PRODUCTS PANEL CROSS SECTION OVERVIEW

The above cross section represents a typical panel, capable of spanning large areas without the need for additional support. A wall panel will typically have pre-stressed cable placed centrally and running horizontally with columns built in and reinforced for stiffness, effectively the panel is classed as a deep beam. All services are pre-tested and cast in. All panels are connected by steel loops and pins encased in EE Fibrecrete making the whole structure monolithic and ideal for aggressive environments. This arrangement developed over 40 years ago is the Gold Standard that other systems have taken elements from. Cellate is so resilient and adaptable it has been used in every sector of construction and used in some of the most iconic buildings in the world.

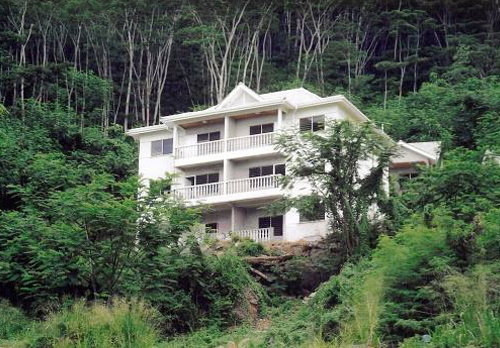

RESIDENTIAL DESIGN OVERVIEW

Cellate precast large panels can be self colored and painted or stained and made to any shape. The larger the panel the less connections and quicker it can be erected. This also adds greater strength to the building and each joint is specially bonded making the structure monolithic which wont crack and is far superior to normal precast concrete and hollow core. Other systems being very difficult to join to the superstructure and has less span to depth ratio than Cellate floor planks thus reducing the number of columns needed.

LOW COST HOUSING OVERVIEW

QUALITY NOT JUST FOR PREMIUM BUILDS

We design and Build a range of affordable property to suit the clients budget and the end users expectations, Cellate panels create value for any building development.

All houses whatever the style are made from Cellate panels and are of the same quality and construction as the Premium buildings.

COMMERCIAL DESIGN OVERVIEW

Given the overall reduced weight of the building, time and expense are further saved by using a raft slab instead of footings or piles. This method is common for smaller buildings but our raft slabs (Celldeck) are especially configured for earthquake zones. As the profile or thickness of the slabs are reduced, this gives a more slender appearance and is ideal for modern Architectural designs. All the walls are insulated and approved for hot climates therefore making the running costs economical.

HOTELS & LEISURE

DESIGN OVERVIEW

Cellate has been used to build a range of hotels and leisure facilities that meet the luxurious expectations. Cellate panels create value and quality for any building development.

All the hotel structure whatever the style are made from Cellate panels have a quality and construction of Premium buildings.

ANTI BALLISTICS

DESIGN OVERVIEW

Objective; Demonstration of impact resistance of Cellate standard panels from small arms fire

Sample: Cellate 100mm thick panel randomly chosen.

Projectile; AR NATO 5.56×45 855(EV: 3,116.8 ft. /s) Date: September 2006

Target: Grouped rounds of 3 at 100yds central and perimeter of target

Penetration: N/A Damage: Light/Surface

Summary: A Cellate standard T1 sample piece was chosen at random from spare material and tested at the Coalition Firing Range Basra Air Base Iraq. The sample showed significant resistance to the high impact round with no penetration. Light Surface damage was observed at the perimeter of the sample with less at the center due to better energy dispersion. Note; T1 panel are standard anti-ballistic rated, T2 are advanced high impact panels not tested.

NOTE: Cellate Ultra High Strength Panels are used to build T-walls, bunkers, military accomodation, data rooms, military command centres, military hard standing, airfield aprons, coastal jetty’s, etc.

Objective; Demonstration of high impact resistance of Cellate panels from heavy loads (BHP Mining Grp)

Sample: Cellate 250mm thick panel wall

Projectile; 20Tonne weighted tipper truck at 100km/hr Date: November 2005

Penetration: N/A Damage: Medium/Surface second skin deformation

A Cellate standard boundary wall was tested at the BHP testing facility in Australia. The sample panel wall displayed substantial resistance to the high impact of the vehicle with no penetration. Medium Surface damage was observed from shockwave propagation to the second outer skin but which remained largely intact. Some deflection was observed from the base of the wall which rebounded to stability whilst the Cellate SFRC retaining posts suffered no terminal damage but underwent a deflection of 11 degrees at the impact zone.

“Cellate advantage” is a collective, defined by excellence, superiority, unbeatable value, time and quality in every application and at every phase delivered beyond the customers expectation”.

Dubai Creek Golf Club constructed with Cellate panels winning the International Best Design Award.

ENGINEERING OVERVIEW

Cellate precast reduces the weight of the entire structure, reducing foundation costs and installation time.

Buildings typically rely upon upon large steel or concrete beams to carry the loads imposed by the floor above.

We will design and construct a multi-functional building using a combination of pre-stressed and post tensioned members including Cellate panels and Cellate fibrecrete floor panels.

Depending on the configuration of the final design, weight may be reduced from 40{c98b2602f8bdf630df8a00c3f517be4b35d71ca19943a82ce1d8721606b20d99} to 60{c98b2602f8bdf630df8a00c3f517be4b35d71ca19943a82ce1d8721606b20d99}.

Cellate conforms to all construction standards and approved globally.

ENGINEERING OVERVIEW

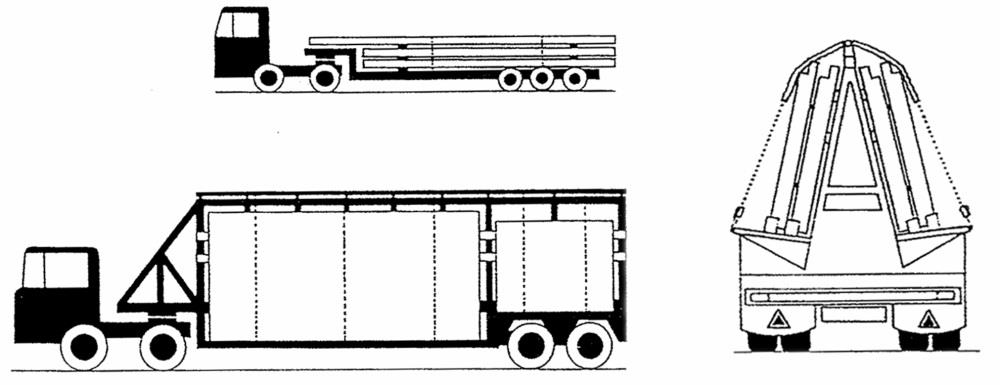

Casting is usually done at site cutting the cost of transportation and produced in a time frame according to the clients program.

A Cellate casting facility can be sophisticated with a degree of automation or very simple depending on the project requirements, location and application. All aspects are considered to provide the best solution to the client and end user, all panels are produced quickly and retain the same high quality finish.

Note all the conduit and pipes are engineered and placed in the moulds and tested before casting cutting down the time for plumbing and electrical trades and are ready to paint.

SAFETY AND QUALITY MANAGEMENT

SAFETY & QUALITY MANAGEMENT POLICY EXTRACTS

We adhere to a zero accident philosophy.

We are committed to a Safety Program requiring that accountability will begin at the highest level of management. Each level of Project Management, Contractor Management, supervision and employees will claim ownership in, and take personal responsibility for their roles in the safety program and will act as a change agent to modify each employee’s behaviour positively towards working safely.

We adhere to ISO9001 – 2015 edition

As leaders in our profession, we must deliver consistently services of the highest Quality that fulfills the expectation of our customers in all our markets. Protection and minimization of the risks to our Clients is the very foundation of our business and organization.

COMPLETED MAJOR PROJECTS LIST

RESIDENTIAL

Umm (Nahad) Damam Local Housing development, Dubai

1000 single story villas ongoing Phase 1 300 successfully completed September 2017

Al Ghadeer housing village Najaf, Iraq

3000 G+1 houses 120,150 and 180 m2 on behalf of the Najaf investment council.

Fishing Village

Hambantota, Sri Lanka H.H. Sheikh Sultan Bin Zayed Al Nahyan.

200 low cost cottages

Low Cost Housing

Sri Lanka

Construction of 2,000 G+2+3 floor apartment units, Director of Ministry of housing and construction,

Grand Parasimut

Bangkok, Thailand

14 Apartment blocks G + 8

Sharjah Residential Tower UAE, HH Sheikh Mohamed Bin Saker Al Nahyan

1 Tower B+G +10 Storey

Cuba Residentia

Havana Cuba – President Fidel Castro –

74 residential Blocks consisting of G +7 story development

Growing House Development Jakarta, Indonesia

2000 low cost housing units

Buccament Bay

Santo Vincente, West Indies

Residential apartments G + 5 design only. Buildings designed for active seismic and tsunami conditions.

Springs Emirates Hills

UAE (EMMAR)

Consisting of 500 Residential villa development, boundary walls.

Future Housing for European Community

Brussels, Belgium

1000 houses consisting of Basement + 4 floors

HOTELS AND LEISURE

Dubai Creek Golf and Yacht Club

Dubai, UAE

Consisting of Sail Structure (2006 best design award)

Barberyn Reef Hotel

Coruvala, Sri Lanka

110 room G + 4 floors

Grand Hyatt Hotel

Dubai, UAE

Consisting of external cladding Entrance reception and main atrium support

Marina Mirage Hotel

Port Douglas Bay, Queensland, Australia

Marina Mirage Hotel

Al Ain Palm Equestrian, Shooting and Golf Club

Al Ain, UAE, Al Zaroni Trans Emirates

Grand Stand Incorporating 30 meter cantilever beams.

The Floating Hotel John Brewer Reef, Queensland, Australia

Tahiti Intercontinental Beachcomber Hotel

Tahiti, French Polynesia

G+2 Hotel resort

Travel Hotel Madol

Nan Madol, Palowi, Pohnpei, Micronesia

G+1 30 room hotel

Hotel Bandung

Yuyuk, Jakarta, Indonesia

5 buildings G+1 20 room Boutique Hotel

Tommy Suharto

Marriott Hotel Dubai, UAE

G+6 storey

COMMERCIAL & RETAIL

Mutual Life Tower

Sydney, Australia

1 Tower 72 storey total height of 228m

(World’s Largest Precast Structure)

World Trade Centre Colombo Sri Lanka

2 (twin) G + 40 storey towers to a height of 152 M

(2nd largest Twin Towers in South Asia)

Al Bustan Shopping Plaza

Sharjah, UAE

G+4 shopping centre.

Up Town Shopping Mall

Bahrain – A. Bassim (Dammam owner)

Complex Multi Geometry G + 4 floors

Abu Dhabi World Trade Centre

Abu Dhabi, UAE

Fibre steel reinforced concrete pre-cast seating platforms

Bank of China

Kuala Lumpur, Malaysia

34 storey tower

MIDF Building

Kuala Lumpur, Malaysia

15 storey office tower

GT Tower 1

Kuala Lumpur, Malasia

G+28 storey

INFRASTRUCTURE

Road Bridge

Hickra Duna Sri-Lanka

Pre-engineered pre-cast bridge

Tunnel Road

Under Harbour Tunnel, Hong Kong

850 m maintenance free road

GOVERNMENT BUILDINGS

Paker Yarsi Medical University

Jakarta, Indonesia

G+14 Storey building with large lecturing faculty within mid section.

McMurdo Sound Research Facility

Antarctica – Australian Government

Housing for research Scientists (temperature differential from -50 degrees)

Mackiti Mablu Floating Mosque

Zanzibar for HE the President Dr. Salmin Amour

Schools Madrassa

Tanzania, on behalf of H.E. Juan Mubarak Al Mazroui, undersecretary for water and power, Abu Dhabi,

50 Schools to facilitate 300 pupils per school

Hospital: Zanzibar, Tanzania

H.E. Juan Mubarak Al Mazroui, undersecretary for water and power, Abu Dhabi

G+5 250 Bed

Sydney Technical University Sydney, Australia

G+7 storey

HARBOURS AND MARINAS

Breakwater Barrier

Trincomale, Sri Lanka

4,800 m2 for Ministry of Defense

Marina Mirage

Surfers Paradise, Gold Coast Queensland, Australia

Marina hovercraft/Heli pad and floating road

Harbour Retaining Wall

Mina Zayed Port, Abu Dhabi

Petron Emirates construction

INDUSTRIAL

Gold Bay Waste Water Plant Gold Bay Canada

1.2 million litre

Mineral Water Bottling Plant Fujairah, UAE

Al Gadhier mineral water plant

Reverse Osmosis Desalination plant, Sharjah UAE

Construction of pre-cast 1 million gallon per day plant including water tanks

Asam A. Al Mulla

Pumping Stations

Fujairah, UAE

Waste water pumping station buildings.

Waste Water Tanks

Dubai UAE

Springs development Cellate fibrecrete tanks

Navitigala Tea Factory Navitigala , Sri Lanka

John Kills, G+4 Floors

Contact Us

Phone: (032) 346-5156

Email: info (@) kelebuilt.com

Address:

Ground Floor, Building 3,

JDN Square, P. Remedio St,

Banilad, Mandaue City,

Cebu, Philippines 6014